Outsource Your Systems

PurposeEnergy designs, builds, owns and operates turnkey, industrial waste treatment systems for food and beverage producers. This approach conserves capital that may be better applied to expanding or improving the food production facility. It also frees management to focus on growing the core business. PurposeEnergy custom designs and operates treatment systems that do more than process wastewater. They also digest high strength residuals like yeast, acid whey, and out-of-spec finished products currently trucked off at high costs. The final step in our process can clean reclaimed water for reuse (think CIP, boiler makeup and washdowns). The entire process generates renewable biogas for use in boilers, electricity-generation, or pipeline injection as Renewable Natural Gas (RNG), all of which significantly reduce the host plants carbon footprint.

Robust Design

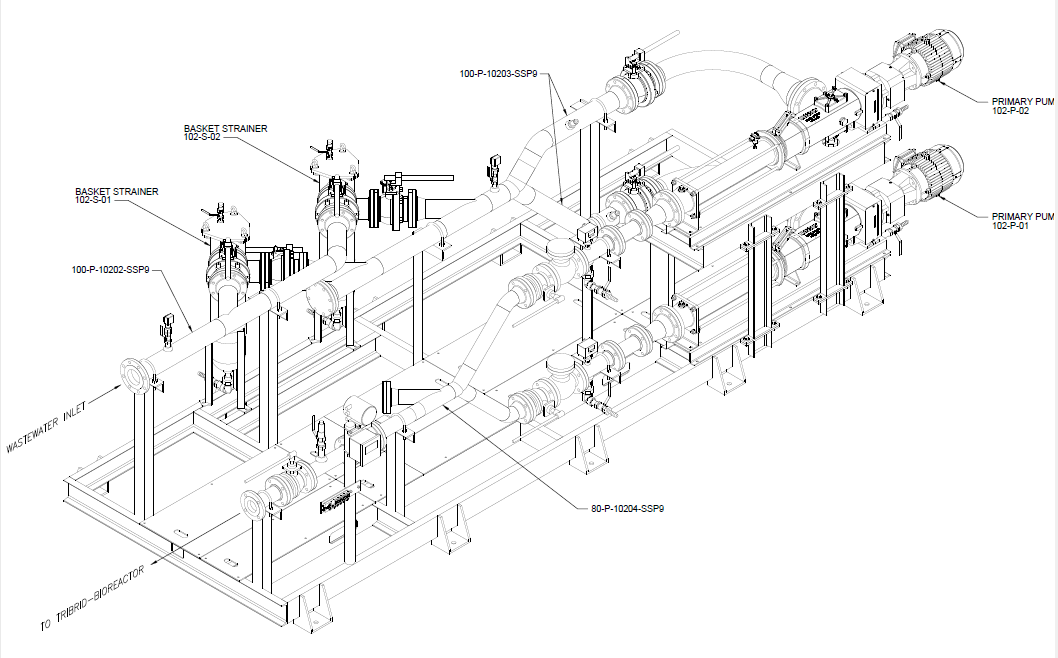

PurposeEnergy’s treatment systems are designed for simplicity. There are no internal moving parts to service, and the entire process can be remotely controlled and operated from a computer or mobile app. Not only is it the most powerful anaerobic digester of its kind, it requires less operational overhead.

Our Efficient Approach

Many elements of our turnkey wastewater solutions are pre-fabricated and then brought to the site for installation. Not only is it more cost-efficient to pre-fabricate components, quality is assured, final assembly on-site is accelerated, production interruptions are minimized during installation, and project safety is enhanced by significantly reducing work hours during construction. Ultimately, our goal is to bring leading production efficiency to water usage, wastewater energy conversion, and carbon management strategies.